ITRI and TEEIA) signed a Memorandum of Understanding (MOU) to jointly promotevirtual IDM (Integrated Device Manufacturer)

On the 21st of this month, ITRI announced the signing of a Memorandum of Understanding (MOU) with the Taiwan Electronic Equipment IIndustry Association (TEEIA). Based on ITRI's world's first wafer-level customisation and high-mix low volume pilot production platform, together with TEEIA's multinational membership in different fields, the two parties will jointly promote the virtual IDM (Integrated Device Manufacturer), with a view to localising heterogeneous integration technology and capturing the international market.

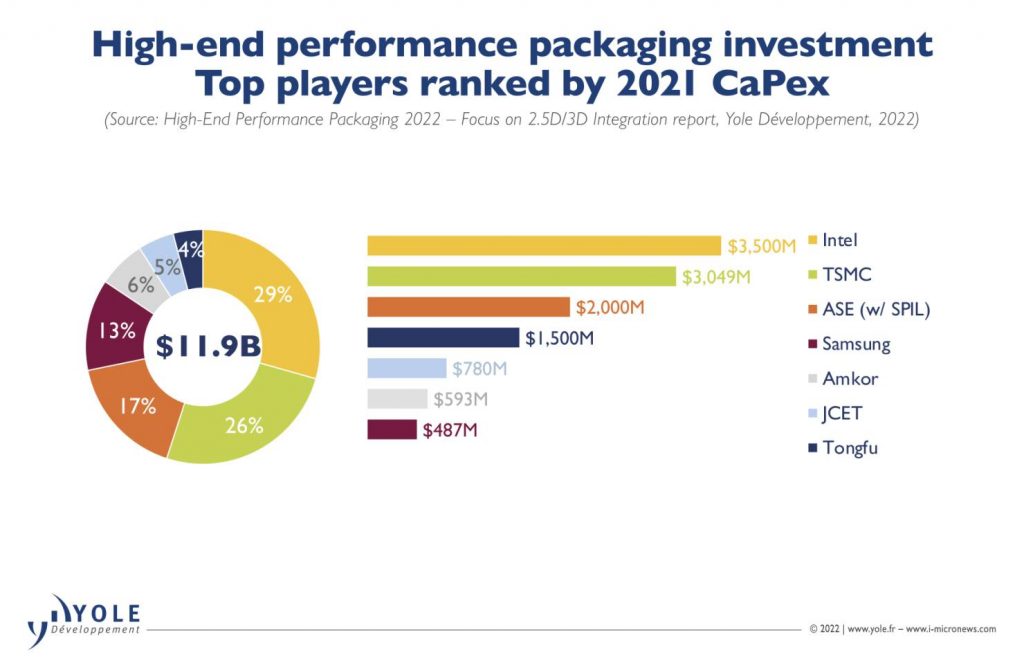

In 2021, CapEx investments of about US$11.9 billion were made in package activity by the top players. Source: Yole

According to data from Yole Developpement, the capital expenditure of the top seven semiconductor factories in 2.5D/3D packaging in the world totaled US$11.909 billion last year. Among them, Intel, TSMC, and ASE Investment Control ranked the top three, with Samsung and Amkor following closely. After that, the mainland packaging and testing manufacturers Changdian Technology and Tongfu Microelectronics also ranked sixth and seventh.

According to the Department of Industrial Technology of MOEA, with the rise of 5G, AI and other emerging technological applications, increasing requirements for packaging, and transistors continuing to go beyond the size limit, the highly heterogeneous "integrated" packaging technology is regarded as the game-changer that will drive the development of the semiconductor industry in the post-Moore era.

Chih-I Wu, Senior Technology Expert of ITRI, pointed out that the miniaturization of manufacturing processes is progressing year by year in the semiconductor industry. 2D/3D Heterogeneous Integration has become a key factor. ITRI plans to use the virtual IDM model to connect domestic enterprises in IC design, manufacturing, packaging and testing, and final device system applications, and to provide full solutions from framework, design, manufacturing to pilot production, so as to shorten the time-to-market and accelerate the transformation and upgrading of the industry.

At present, ITRI is calling on domestic and foreign semiconductor-related industries to establish the Heterogeneous Integration Package Development Alliance, which will provide a platform for international institutes, IEEE, SEMI, and start-up enterprises.

Together with TEEIA, ITRI hopes to promote a one-stop solution by using the world's first wafer-level pilot production platform to help industry players build localised industries and conduct testing and certification in Taiwan. This will not only reducing manufacturing costs and increasing productivity, but also achieve the synergy and value in the interaction in business networks.

Wang Zuojing, Chairman of TEEIA, said that there are 250 manufacturers in the association, with the proportion of small and medium-sized enterprises (SMEs) as high as 90%, covering the fields of semiconductors, panel displays, printed circuit boards (PCBs), solar cells and LED equipment.

TEEIA and ITRI and other organisations collaborated in 2018 to publish a white paper on Taiwan's electronic equipment industry, focusing on semiconductor equipment, next-generation display equipment, intelligent manufacturing systems, intelligent testing equipment and industry intelligent systems and intelligent services. They also put forward the vision of Innovation X (a decade of innovation in Taiwan's electronic equipment industry), in the hope of makting electronic equipment industry Taiwan's next trillion-dollar industry by 2028.

ITRI and TEEIA signed a Memorandum of Understanding (MOU) to achieve the goal of localisation of heterogeneous integration technology