Contrel’s FOPLP technology addresses critical challenges in semiconductor packaging, particularly in high-frequency applications such as 5G, artificial intelligence (AI), and Internet of Things (IoT). Utilizing state-of-the-art laser processing methods, the company has revolutionized traditional panel-level manufacturing, overcoming limitations related to efficiency and accuracy.

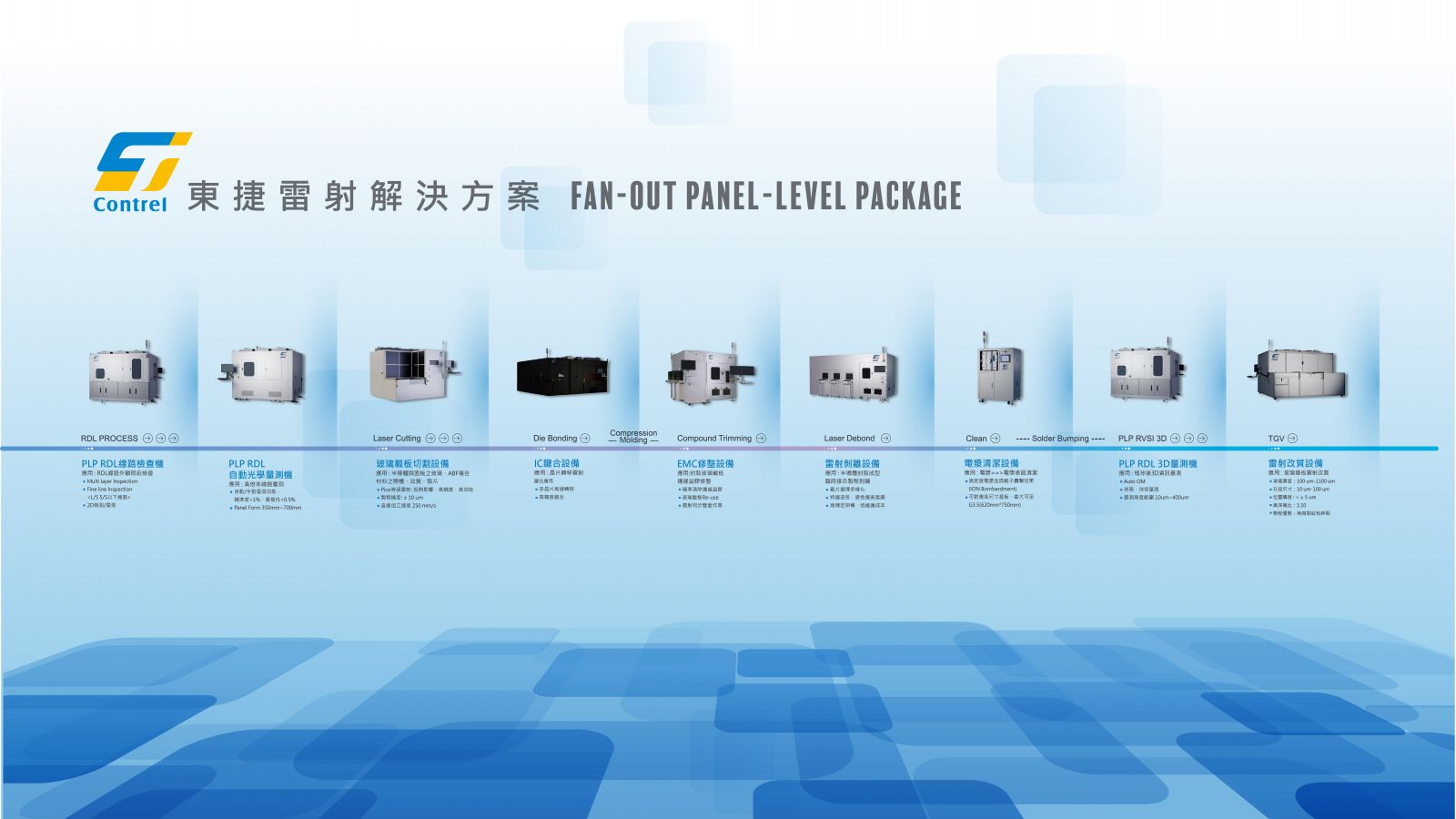

Contrel Technology’s FOPLP laser solutions effectively offering a complete set of advanced equipment, including:

- 3D Automated Optical Inspection Equipment:

RDL AOI can automatically classify and repair defects, and is the savior of large-size panel-level packaging yield.

- Glass Substrate Laser Cutting Equipment:

The glass cutting machine is equipped with a dual-laser dual-axis structure with ultra-fast laser modification and CO2 thermal cracking, which can quickly and automatically cut freeform transparent hard and brittle materials. Contrel’s glass laser cutting equipment has the most application results in Taiwan.

- EMC (Epoxy Molding Compound) Laser Trimming Equipment:

Laser synchronous double-sided operation technology is used to accurately remove excess glue from the edges, allowing the glass carrier to be reused after the peeling process, allowing packaging factories to reduce glass scrap costs and reduce environmental damage in line with the ESG spirit.

- Laser Debonding Equipment:

Optimizes stability and efficiency by fast & large-area laser scanning technology in the debonding process.

Moreover, Contrel Technology collaborates with Taiwan's leading vacuum equipment supplier F.S.E. Technology to introduce key equipment, including plasma descum and Cu seed layer sputtering systems. These innovations collectively form a comprehensive ecosystem for FOPLP laser solutions, flexibly addressing the diverse requirements of the semiconductor supply chain.

TGV Technology

Contrel’s groundbreaking TGV technology exemplifies its vision for sustainable and advanced semiconductor manufacturing. Through meticulous engineering and proprietary processes, Contrel’s TGV solutions achieve the industry's highest positioning accuracy and roundness capabilities. And redefine vertical interconnect technologies in glass substrates. By employing high-energy laser drilling and automated coating techniques, Contrel achieves exceptional uniformity and reliability, meeting the stringent requirements of high-frequency and thermal management applications.

With its environmental responsibility in mind, Contrel ensures that its TGV processes adhere to green manufacturing principles, minimizing energy consumption and optimizing resource utilization. The company’s commitment to sustainability aligns with global efforts to reduce ecological impact and pave the way for eco-friendly technological advancements.

Customer-Centric Vision

Guided by the principles of innovation, collaboration, and customer-centricity, Contrel is dedicated to fostering strong partnerships with global clients. Its customized technical support, combined with cutting-edge solutions, ensures that clients receive the highest quality products tailored to their unique requirements.